What Is a Cobot Welding

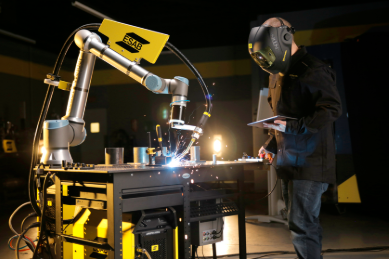

In the evolving world of manufacturing, cobot welding is emerging as a game-changing technology that blends human skill with robotic precision. A cobot welding system uses collaborative robots designed to work safely alongside human operators while performing welding tasks with consistent accuracy.

This approach not only boosts productivity but also improves weld quality and reduces operator fatigue. In this guide, we will explore what cobot welding is, how it works, and why it is becoming an increasingly valuable solution in modern fabrication.

What Is a Cobot?

A cobot (collaborative robot) is a robot that can safely work side by side with people. Unlike regular robots that require fences or barriers, cobots have sensors and safety features that enable them to stop or slow down if a person is nearby. This makes them safe, easy to use, and great for helping humans with different tasks.

What Is Cobot Welding?

Cobot welding uses collaborative robots (cobots) with welding tools like MIG, TIG, or laser welders to make the welding process faster and easier. They’re simple to program, very precise, and consistent, which makes them useful for both basic and advanced welding jobs. Even workers without much robotic knowledge can quickly learn to use them, helping businesses save time, improve weld quality, and boost efficiency.

How Cobot Welding Works: Main Parts & Workflow

- Cobot Arm

A cobot arm is a lightweight robotic arm that guides the welding torch with high precision. Its multiple joints provide flexibility, making it easy to reach and weld at difficult angles.

- Welding Power Source & Torch

The cobot holds a MIG, TIG, laser, or spot welding torch. It connects to a professional power source to control voltage, current, and wire feed for accurate welds.

- Safety Features

Cobots use sensors to stop or slow near people, and welding hazards are controlled with added protection like curtains or partitions.

- Easy Programming & Controls

Cobots are easy to use because they don’t require complicated coding. Operators can program them through a touchscreen, tablet, or by guiding the arm manually.

- Workflow: From Setup to Weld

- Setup: Connect power and gas, place the part.

- Teach: Guide the cobot or use the interface to set the weld path.

- Program: Adjust welding settings or pick from presets.

- Execute: Press start, and the cobot will weld the same way every time, giving consistent results.

Cobot welding makes welding easier, more precise, and reliable, while helping fill gaps when skilled welders are unavailable.

Benefits of Cobot Welding

Cobot welding offers many advantages that improve efficiency, safety, and flexibility in manufacturing.

- Higher Productivity

Cobots can work all day and night without breaks, keeping production running smoothly. They handle repetitive or time-consuming tasks, so factories can make more products faster and at lower cost. This also gives workers more time to focus on important jobs that need skill or creativity. - Better Precision and Consistency

With advanced sensors and precise programming, cobots perform tasks with accuracy and consistency. In welding, for example, they deliver clean, repeatable welds, reducing errors, material waste, and rework. The result is improved product quality and greater customer satisfaction. - Cost Efficiency

Cobots are generally more affordable than traditional industrial robots. They are easier to purchase, set up, and maintain, and they integrate smoothly into existing workflows. This reduces initial investments and enables companies to achieve quicker returns on their automation efforts. - Improved Safety

Cobots take on difficult or dangerous tasks, such as lifting heavy objects, welding, or working with harmful materials. This reduces accidents and injuries, helping keep workers safe. - Flexibility and Scalability

Cobots are lightweight and easy to reprogram. They can be quickly moved to new tasks or production lines, making them adaptable to new products, changing demands, or smaller production runs. - Helping With Labor Shortages

When skilled workers are in short supply, cobots can take over routine tasks such as welding and assembly. Cobots keep production running smoothly while freeing skilled workers to focus on complex tasks.

Using cobot welding can boost productivity, improve quality, enhance safety, and save costs, making it a smart investment for modern manufacturing.

Challenges and Considerations in Cobot Welding

Cobot welding provides many benefits, but there are also challenges to consider before implementing them in your operations.

- Upfront Costs and Integration

Buying and setting up cobots costs money at the start. You may also need to spend extra on adjusting your current equipment and workspace so the cobot can work safely, which requires careful planning.

- Task Suitability and Limitations

Cobots work best for light, repetitive welding tasks. They aren’t designed for very large or heavy welds, where traditional industrial robots may still be required.

- Programming and Skill Requirements

Cobots are easier to program than traditional robots, but you still need trained operators to set the right welding settings. If operators lack proper knowledge, welds can turn out uneven or poor. Training and experience ensure accurate, reliable welds.

- Workspace Adaptation

Setting up cobots may mean rearranging your workspace and changing how materials are handled. If these changes aren’t planned carefully, they can temporarily slow down work and lower productivity.

- Rapid Technological Changes

Robotics technology evolves quickly, so today’s cobot may become outdated sooner than expected. Keeping up with updates and potential upgrades can add costs over time.

Cobot welding has many advantages, but businesses should carefully consider costs, task suitability, skills, workspace needs, and technology updates to ensure a smooth and successful integration.

Future Trends in Cobot Welding

- AI & Machine Learning

Cobots are getting smarter with AI. They can automatically adjust welding settings while working, spot mistakes or defects as they happen, and even predict weld quality. Many are now connected to smart factories and can be used through subscription plans.

- Advanced Safety & Sensors

Modern cobots use sensors, cameras, and thermal imaging to detect people, welding seams, and obstacles around them. Their safe design and built-in limits on force help prevent accidents and make workplaces much safer.

- Growing Industry Adoption

The cobot market is expanding rapidly. Key sectors include automotive, electronics, metals, and small to mid-sized manufacturers. Cobots are also helping industries cope with skilled labor shortages.

Conclusion: Cobot Welding

Cobot welding represents a transformative approach in modern manufacturing, combining human expertise with robotic precision. By using collaborative robots, factories can achieve safer, more consistent, and higher-quality welds while reducing operator fatigue and addressing labor shortages.

Cobots are flexible, easy to program, cost-effective, and capable of handling a variety of welding tasks, making them ideal for small-batch production and evolving manufacturing needs. Despite initial costs and limitations, cobot welding’s productivity, safety, precision, and flexibility make it a smart investment.

AI and smart factory tech are making cobots key to the future of automation. Cobot welding not only optimizes production efficiency but also empowers workers and businesses to stay competitive in a rapidly evolving industry.